Products

Insulation Paper / Film / Tape

-

-

Product Introduction

- DMD(155℃、180℃)、PAI/PET/PAI(180℃)、PAI(220℃)、PI(240℃) Insulation Paper

- PET(130℃)、PI(260℃、280℃) Insulation Tape

- Use solvent-free bonding Darcon and Mylar

- No blistering, curling, delamination, cracking at 200℃

- Increased dielectric strength values – up to 15% - over 10,200 Volts

- DMD (155℃、180℃)

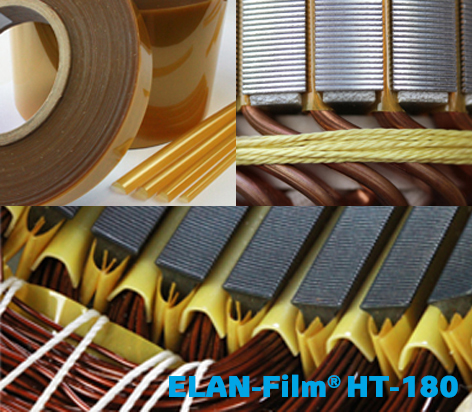

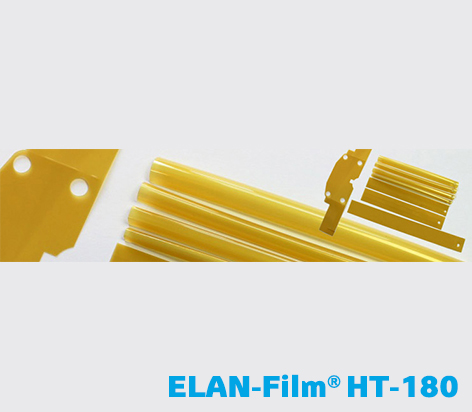

- HT-180 (180℃)

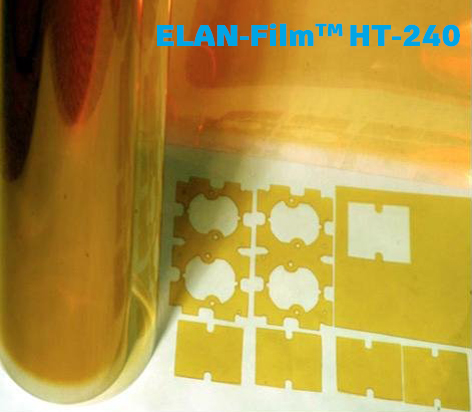

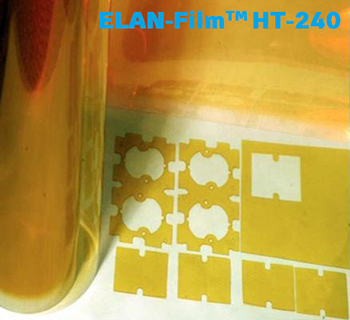

- HT-240 (240℃)

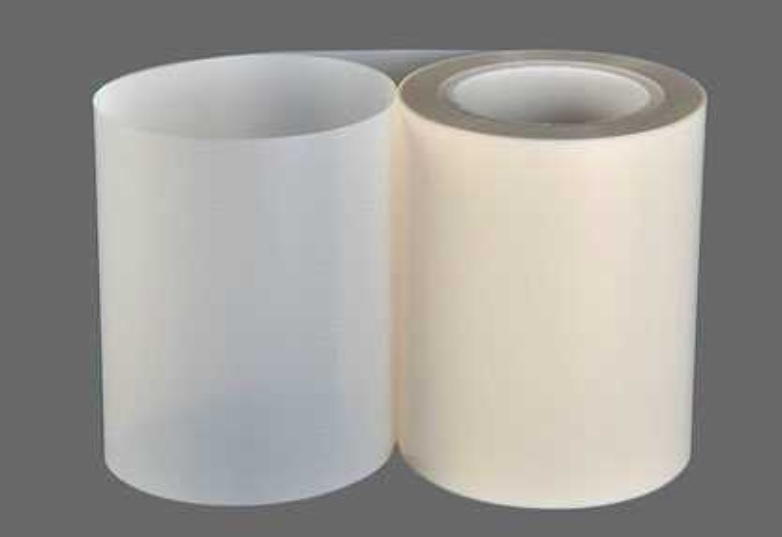

- PET film

- NMN (180℃)

- DM Blue (155℃)

- Tape

| Specifications | Thermal Rating |

Thickness (mm) |

Breakdown Voltage (volts) |

Tensile Strength (lb/in) |

Dielectric Constant |

Dissipation Factor |

Volume Resistivity (ohm-cm) |

Surface Resistivity (ohms/cm2) |

|

|---|---|---|---|---|---|---|---|---|---|

| MD | XD | ||||||||

| 2-2-2 | F | 0.006 (0.15) |

8,050 | 85 | 75 | 2.9 | 0.09 | 1015 | 1016 |

| 2-3-2 | F | 0.007 (0.18) |

10,200 | 100 | 95 | 3.1 | 0.05 | 1015 | 1015 |

| 2-7.5-2 | F | 0.012 (0.29) |

15,300 | 190 | 180 | 2.8 | 0.07 | 1015 | 1015 |

| 3-3-3 | F、H | 0.009 (0.23) |

10,200 | 130 | 100 | 3.2 | 0.08 | 1015 | 1015 |

| 3-5-3 | F、H | 0.011 (0.28) |

13,200 | 165 | 135 | 3.2 | 0.07 | 1015 | 1016 |

| 3-7.5-3 | F、H | 0.014 (0.34) |

15,500 | 215 | 205 | 3.3 | 0.07 | 1015 | 1015 |

| 3-10-3 | F、H | 0.016 (0.41) |

16,400 | 260 | 250 | 3.7 | 0.07 | 1015 | 1015 |

| 3-14-3 | F、H | 0.020 (0.51) |

16,900 | 315 | 305 | 3.2 | 0.01 | 1016 | 1016 |

| 5-3-5 | F、H | 0.013 (0.33) |

10,100 | 190 | 170 | 2.9 | 0.01 | 1014 | 1014 |

| 5-5-5 | F、H | 0.015 (0.38) |

15,800 | 210 | 185 | 3.2 | 0.01 | 1015 | 1016 |

| 5-10-5 | F、H | 0.020 (0.51) |

18,300 | 280 | 235 | 3.5 | 0.01 | 1014 | 1014 |

| 5-14-5 | F、H | 0.024 (0.61) |

19,500 | 300 | 285 | 3.0 | 0.03 | 1015 | 1014 |

| Thickness and Composition of ELAN-Film® HT-180 | |

|---|---|

| Composition | PET film coated PAI on each side |

| Thickness | 3 mil – 26 mil (75 µm – 660 µm) |

| UL Classification Property | ||||

|---|---|---|---|---|

| Property | Test Method | Unit | Value | Class |

| Thermal Classification | UL 1446 | °C | 180 | H |

| Electrical Properties of ELAN-Film® HT-180 | |||||

|---|---|---|---|---|---|

| Property | Test Method | Units | 4.5 mil film (114 μm) | 7.5 mil film (190 μm) | 11 mil film (279 μm) |

| Dielectric Strength | ASTM D149 | Volts | 11,100 | 14,300 | 16,100 |

| Volume Resistivity | ASTM D257 | ohms-cm | 1015 | 1015 | 1015 |

| Surface Resistivity | ASTM D257 | ohms/square | 1013 | 1014 | 1014 |

| Water Absorption of ELAN-Film® HT-180 | |||||

|---|---|---|---|---|---|

| Property | Test Method | Unit | 4.5 mil film (114 μm) | 7.5 mil film (190 μm) | 11 mil film (279 μm) |

| Water Absorption | Full immersion of test sample in water for 24 hours @ 25°C | Percent gain | 0.7 | 0.5 | 0.4 |

| Dissipation Factor and Dielectric Constant of ELAN-Film® HT-180 in Humid Environments (8.5 mil / 215 μm total film thickness) |

||||||

|---|---|---|---|---|---|---|

| Conditions (DC and DF tested @ 25°C) |

Dielectric Constant | Dissipation Factor | ||||

| 100 Hz | 500 Hz | 1 kHz | 100 Hz | 500 Hz | 1 kHz | |

| Tested as is | 2.4 | 3.1 | 3.4 | 0.03 | 0.003 | 0.008 |

| After 168 hours in 100% humidity at 40° C | 2.2 | 3.1 | 3.7 | 0.02 | 0.005 | 0.008 |

| Adhesion of ELAN-Film® HT-180 with impregnating resins | ||

|---|---|---|

| Material | Curing conditions | Adhesion |

| Alkyd resin | 2 hrs @150 °C | Excellent |

| Waterborne polyester | 2 hrs @150 °C | Excellent |

| Epoxy emulsion | 2 hrs @165 °C | Excellent |

| Unsaturated polyester in VT |

2 hrs @150 °C | Excellent |

| Epoxy | 4.5 hrs @160 °C | Excellent |

| Freon Extraction of ELAN-Film® HT-180 | |||||

|---|---|---|---|---|---|

| Property | Test Method | Units | 4.5 mil film (114 μm) |

7.5 mil film (190 μm) |

11 mil film (279 μm) |

| Weight loss upon Freon extraction |

Weight percent | 0.1 | 0.1 | 0.1 | |

| Mechanical Properties of ELAN-Film® HT-180 | |||||

|---|---|---|---|---|---|

| Property | Test Method | Units | 4.5 mil film (114 μm) |

7.5 mil film (190 μm) |

11 mil film (279 μm) |

| Tensile Strength | ASTM D882 | MPa | 137 | 134 | 107 |

| Tensile Modulus | ASTM D882 | MPa | 3235 | 3150 | 2360 |

| Tear Strength | ASTM D1004 | N/mm | 378 | 394 | 388 |

| Elongation | ASTM D882 | % | 88 | 106 | 144 |

| Thermal Conductivity of ELAN-Film® HT-180 | ||||

|---|---|---|---|---|

| Property | Film Thickness | Test Method | Temperature, ℃ | Result, W*m-1*K-1 |

| Thermal Conductivity | 8.5 mil (215 μm) | ASTM E 1530 | 25 | 0.19 |

| 90 | 0.18 | |||

| 125 | 0.18 | |||

| 11 mil (279 μm) | ASTM E 1530 | 25 | 0.20 | |

| 90 | 0.19 | |||

| 125 | 0.19 | |||

Standard of ELAN-Film® HT-240

| Part No. | HT-240 GP | HT-240 HP | HP-240 SD |

|---|---|---|---|

| Composition | Polyimide | Polyimide | Polyimide |

| Thickness | 13 µm – 225 µm | 13 µm – 75 µm | 13 µm – 75 µm |

| UL94 Flammability | V-0 | V-0 | V-0 |

| Dielectric Strength | ≧ 100 MV/m | ≧ 200 MV/m | ≧ 200 MV/m |

| Tensile Strength | ≧ 115 MPa | ≧ 160 MPa | ≧ 160 MPa |

| Tensile Strength | 40% | 40% | 30% |

| Density | 1.43 | 1.43 | 1.43 |

| Volume Resistivity | >1010 | >1015 | >1015 |

| Surface Resistivity | >1014 | >1015 | >1015 |

| PET film | |

|---|---|

| Composition | PET film |

| Color | Milky white、Transparent |

| Thickness | 0.125mm、0.188mm、0.25mm Other thickness can be customized according to customer’s requirement. |

| Width | Standard width (1000mm) or slitting into required width(s) |

| NMN paper | |

|---|---|

| Composition | Aramid-PET-Aramid |

| Color | off white |

| Thickness | 0.15mm、0.18mm、0.23mm、0.28mm、0.30mm、0.35mm、0.38mm、0.46mm Other thickness can be customized according to customer’s requirement. |

| Width | Standard width (1000mm) or slitting into required width(s) |

| DM Blue paper | |

|---|---|

| Composition | polyester fabric-PET |

| Color | Blue or Other colors can be customized according to customer’s requirement. |

| Thickness | 0.15、0.20、0.25、0.30 Other thickness can be customized according to customer’s requirement. |

| Width | Standard width (1000mm) or slitting into required width(s) |

Insulation Tape

| Material | Part No. | Thermal Rating | Thickness | Dielectric Strength |

|---|---|---|---|---|

| Mylar Tape | T-1 | 130 ℃ | 0.055 mm | 5 (KV/mil) |

| Acetate Tape | T-3 | 105 ℃ | 0.27 mm | 2 (KV/mil) |

| Polyimide Tape | HT-240 GP25/S30 | -73 – 260 ℃ | 0.055 mm | 5 (KV/mil) |

| Fiberglass Tape | JOT-33 | 200 ℃ | 0.22 mm | 2 (KV/mil) |

| Aremco Tape | 682-TB | 1371 ℃ | 0.76mm 1.37mm |

NA |

Fiber tape with B stage epoxy resin

| Part No. | Thickness | Epoxy resin | Curing | Application |

| 5100 | 0.1mm | 66% | 150C*30min or 120C*2hr |

heat cure the tape resin for high fixed strength especially for magnet on motor |

-

Taipei Office

TEL:886-2-26008672FAX:886-2-26008673

(244019)No. 38-1, Pa-Teh Road,Lin-Kou Dist., NewTaipei City, Taiwan. -

Taichung Office

TEL:886-4-25685848FAX:886-4-25685857

No. 12-1, Qiancun E. Rd., Daya Dist., Taichung City 428017, Taiwan -

Dongguan Office

TEL:86-769-88188707FAX:86-769-88188709

(523221)No.456, Nanhuang Road, Huangyong Village, Zhong Tang Town, Dong Guan City, Guang Dong Province, P.R.C -

Vietnam Office

TEL:84-989-243884

FL 2, Trung Yen building 1, Trung Yen, Trung Hoa, Cau Giay, Hanoi, Vietnam.

-

Copyright © JASDI CHEMICALS CO., LTD.

Designed by Taiwan Products, B2BChinaSources, B2BManufactures